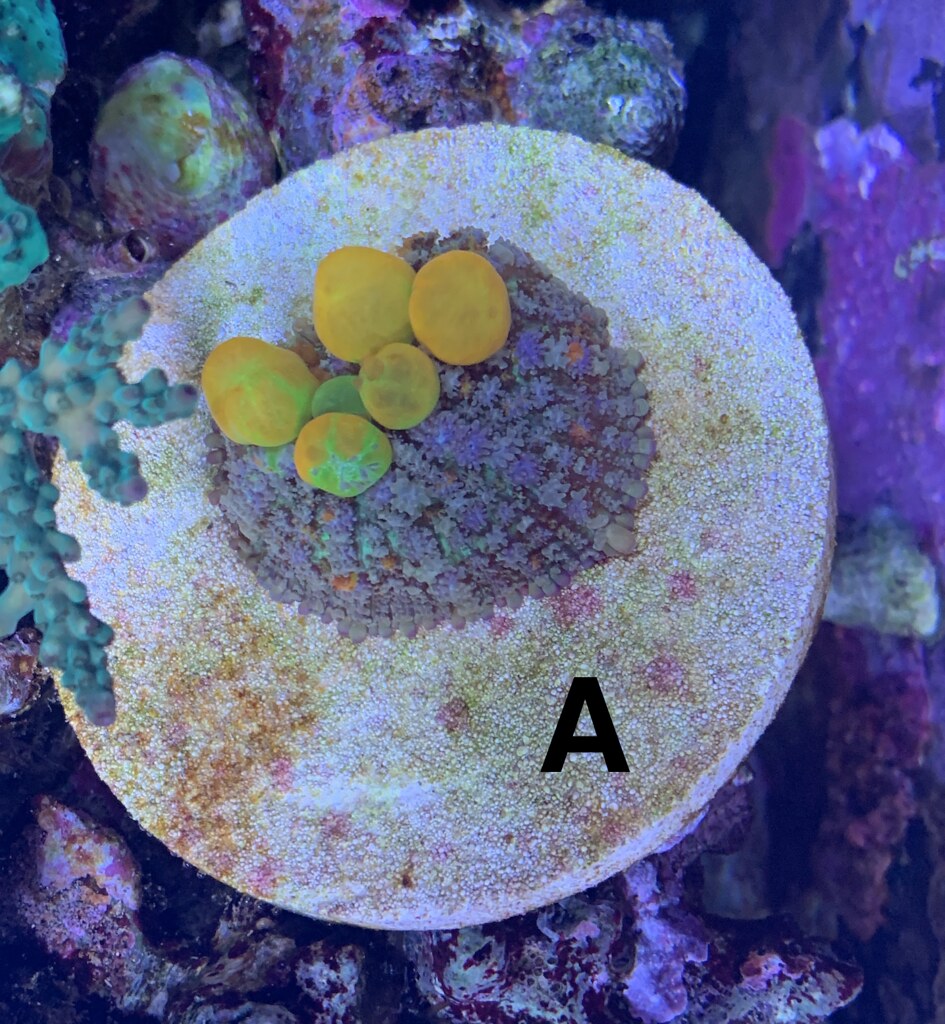

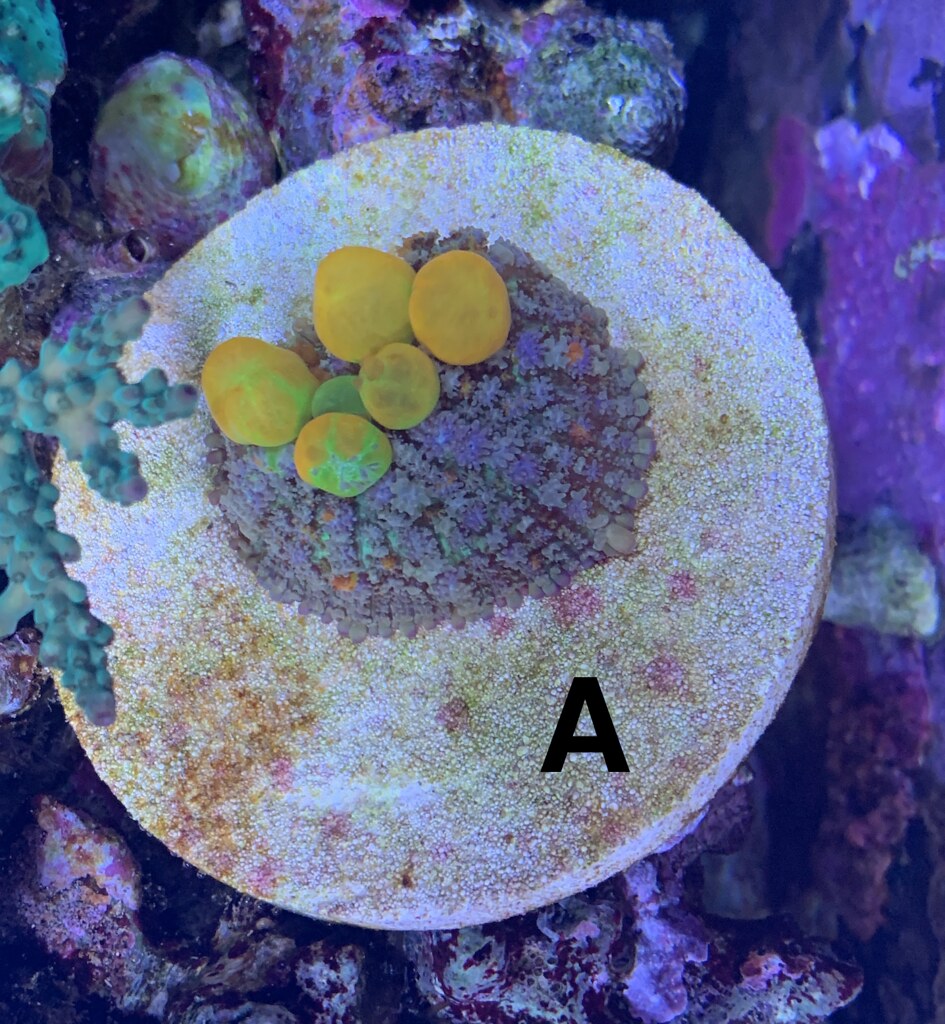

One of my big ones tore it's self apart a few weeks ago, so now I have a bunch. These are three inch frag discs. These are also at the top of my tank under MH at about 450-500 PAR, so these are really small right now - wanted to do this to show the minimum size... they would be larger with less light. I would rather undersell them since they do inflate to different sizes with available light.

Mostly just want to sell. I am REALLY picky to trade with, but I am open to offers.

Pick up in Longmont. These are no-shipping prices, but I can ship for a bit more.

A: 1000 - SOLD

B: 275 - SOLD

C: 325 - SOLD

D: 275 - SOLD

E: 350 -SOLD

F: 1000 - SOLD

The big ones could be cut into quarters and then sold for 300+. F is the largest.

Mostly just want to sell. I am REALLY picky to trade with, but I am open to offers.

Pick up in Longmont. These are no-shipping prices, but I can ship for a bit more.

A: 1000 - SOLD

B: 275 - SOLD

C: 325 - SOLD

D: 275 - SOLD

E: 350 -SOLD

F: 1000 - SOLD

The big ones could be cut into quarters and then sold for 300+. F is the largest.

Last edited by a moderator: